Essential in historical moments.

Innovating new ways for the world to move, power, connect and protect means our products can be found in the stories of seminal moments of history.

A culture of relentless innovation permeates our history. Combined with our equal passion to care for the natural world and the communities in which we operate, we are proud to continue a legacy of building a more resilient world.

Essential in historical moments.

Innovating new ways for the world to move, power, connect and protect means our products can be found in the stories of seminal moments of history.

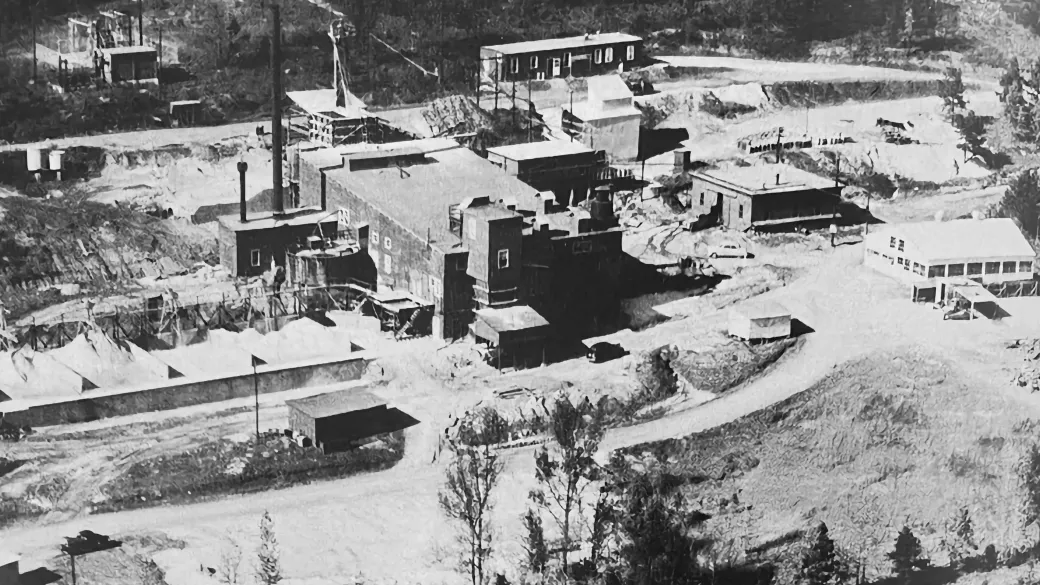

Legacy of Lithium

Albemarle’s Kings Mountain, North Carolina operations, atop one of the richest spodumene ore deposits in the world, played a critical role in the 1950s when the United States Atomic Energy Commission contracted it to supply Li-6. Lithium from the Kings Mountain site was also used for decades in the production of stronger aluminum and steel, as a lubricant for aircraft engines and to create hydrogen gas for observation balloons.

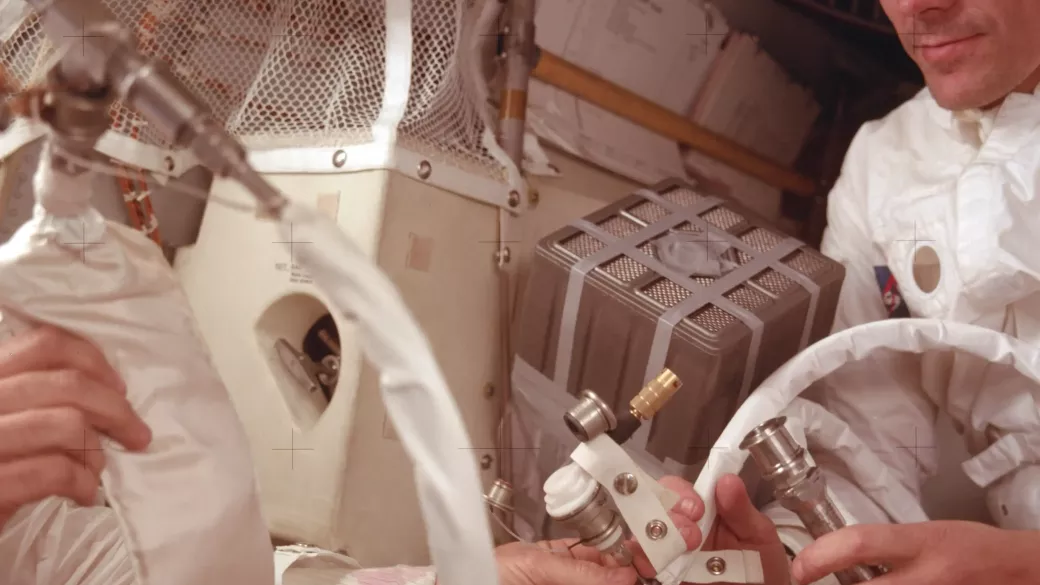

“Houston, we have a solution.”

In 1970, Albemarle scientific and chemical process know-how played an unexpected vital role in the now infamous Apollo 13 mission. It was scheduled to be NASA’s third mission to take astronauts to the moon’s surface, but an explosion of one of the oxygen tanks and subsequent damage to other systems resulted in the mission being cut short before the planned landing could take place. With the oxygen tanks depleted, the command module was unusable and the crew of four transferred to the lunar module, designed for a maximum of two crew members for a much shorter duration than the emergency required.

Albemarle scientists deeply experienced in working with lithium hydroxide, deployed their chemical process knowledge for an air-purifying CO2 scrubbing solution. This provided the astronauts with oxygen for several days while 200,000 miles from Earth a complex – and ultimately successful – reentry plan was devised.

Today, Albemarle materials and chemical expertise continues to support life-saving breathing technologies from portable medical grade oxygen systems widely used in the COVID-19 pandemic to Emergency Escape Breathing Devices (EEBD) that provide adequate oxygen for sustaining human life in non-breathable atmospheres.

Photograph of Jack Swigert and the lithium hydroxide cannister onboard the Apollo 13 lunar module.

A global pandemic response.

During the COVID-19 global pandemic, Albemarle’s ongoing role in the production and safe use of portable oxygen and was essential to meet the sharp rise in lifesaving ventilation and breathing devices. Our process chemistry know-how allowed us to rapidly convert manufacturing sites to produce disinfectants, including thousands of gallons from the Langelsheim, Germany site while Albemarle’s hydrobromic acid continued to support the production of lifesaving personal protective equipment.

“I am proud we are able to use our expertise in the manufacture of chemical products for the health of our fellow citizens.”

A history of partnership.

A highly integrated player in many essential value chains, Albemarle knows partnering to pioneer is often the best way to serve people and planet.

Joint Ventures

Joint ventures have fueled both growth and innovation in our history and continue to play a vital role in our future progress.

Partnerships

Collaborating with like-minded scientists, academia, local experts and customers is in our DNA. It has always allowed us to solve problems smarter and faster while assuring we have all stakeholders in mind.

Commercial Partners

Albemarle has always partnered with a wide range of companies, including many customers across all our businesses to advance common goals in research and development as well as their own proprietary business strategies. Recent examples include Sandia Labs, Caterpillar, Ford, BMW, and more.

Academic Partners

Albemarle has long believed in the power of global academic engagement for research collaboration as well as workforce development. Together, we continue to inspire the next generations of scientists, engineers and doers in the specialty chemicals world.

Stewarding Finite Natural Resources

Our leadership in safety and sustainability runs deep at Albemarle. Detailed safety programs for manufacturing as well as care for our communities date to the early 1900s. Today our culture of safety and sustainability is stronger than ever due to continued investments and global public alignment on the importance of caring for people and planet today and for generations to come.

From our inception: A better way to move, power, connect, protect. Albemarle has always sought a better way – a better way to work, to produce and to serve our customers, people, communities and planet. Explore our history here.

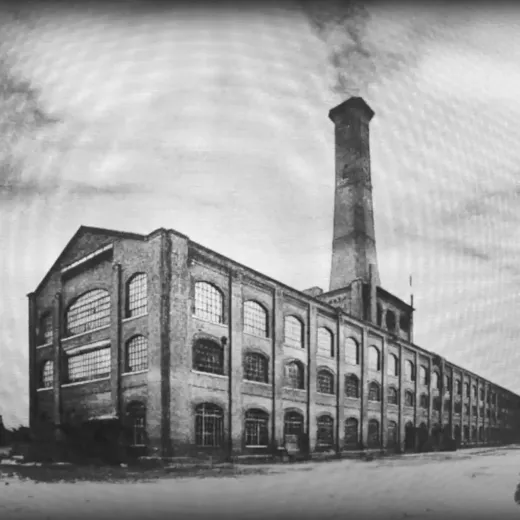

1887: Albemarle Paper Manufacturing Company founded in Richmond, Virginia

1900s: Solid financial success as a world-leading blotting and kraft paper manufacturer

1930s: Purchased the first kraft pulp mill in the US in Roanoke Rapids, NC, to assure domestic supply

1950s: Forward integration through acquisitions and investments in bag and box manufacturing companies; modernized large-scale paper production machinery

1969: Bromine operations begin in Magnolia, Arkansas

1976: Company sells remaining paper manufacturing to focus on specialty chemicals

1994: Albemarle Corporation becomes publicly traded entity; expands in Asia and Europe in late 1990s

1998: Joint venture with Jordan Dead Sea Industries Company (JODICO) and Arab Potash Company (APC) for bromine production on global scale

2000s: Strategic acquisitions including Akzo Nobel NV catalysts, ChemFirst, Martinswerk GmbH, DSM Pharmaceutical Products fine chemistry and others

2008: Headquarters move from Richmond, VA, to Baton Rouge, LA

2010: Budapest global shared services center opens

2012: Process Development Center (PDC) laboratory facility opens in Baton Rouge, LA

2015: Albemarle moves HQ to Charlotte, NC with acquisition of Rockwood Holdings, premier specialty chemicals company with complementary leading positions in lithium and bromine

2019: Significant lithium expansion in Western Australia: stake in Wodgina Hard Rock Lithium Mine and launch of Kemerton Lithium Project

2023: Focus on specialty chemicals and energy storage global business units; launched Ketjen as the official brand of catalysts

What’s In A Name?

“At 9:15 on Friday evening, February 11, 1887, five businessmen – J.F. Chalmers, G.A. Cunningham, Thomas S. Flournoy, Jr., W.E. Dibrell, and E.B. Thaw – met at Murphy’s Hotel, corner of Eighth and Broad [Richmond, VA] to consider the matter of forming a company for the manufacture of paper …. W.E. Dibrell, editor of the Southern Tobacconist … proposed corporation be entitled “Albemarle Paper Manufacturing Company’’ .… nobody has ever presented a convincing reason as to why ‘Albemarle.’ So far as can be discovered, he had no connection with Albemarle County in Virginia, the Albemarle section of North Carolina, or that portion of the Normandy coast of France that once went under that label. Apparently the syllables simply pleased his ear."

— from “ETHYL: A History of the Corporation and the People Who Made It” by Joseph C. Robert. The University Press of Virginia, Charlottesville; first published in 1983.