MERCURY CONTROL FOR CLEANER ENERGY: WE PUT THE POWER IN YOUR PLANT.

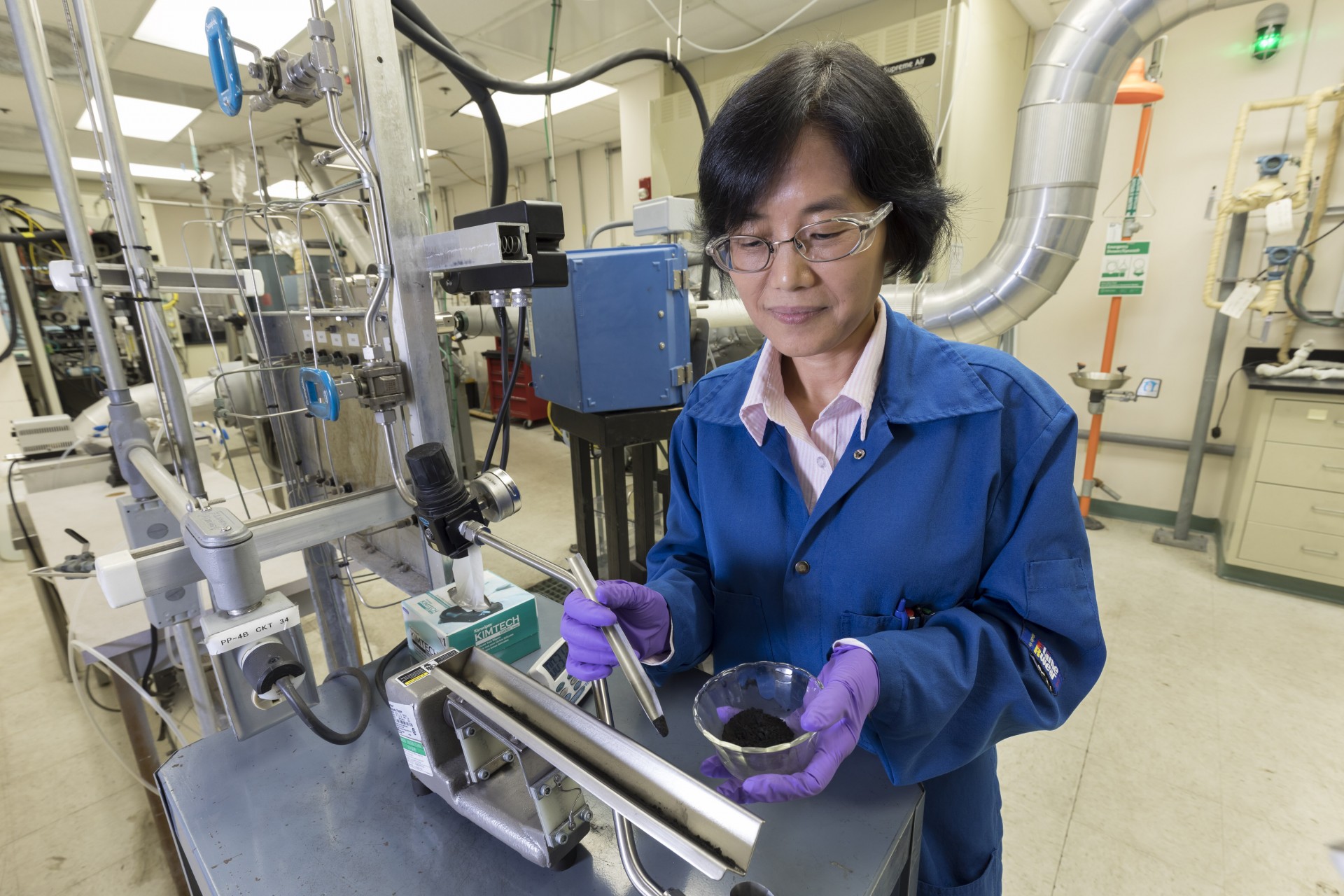

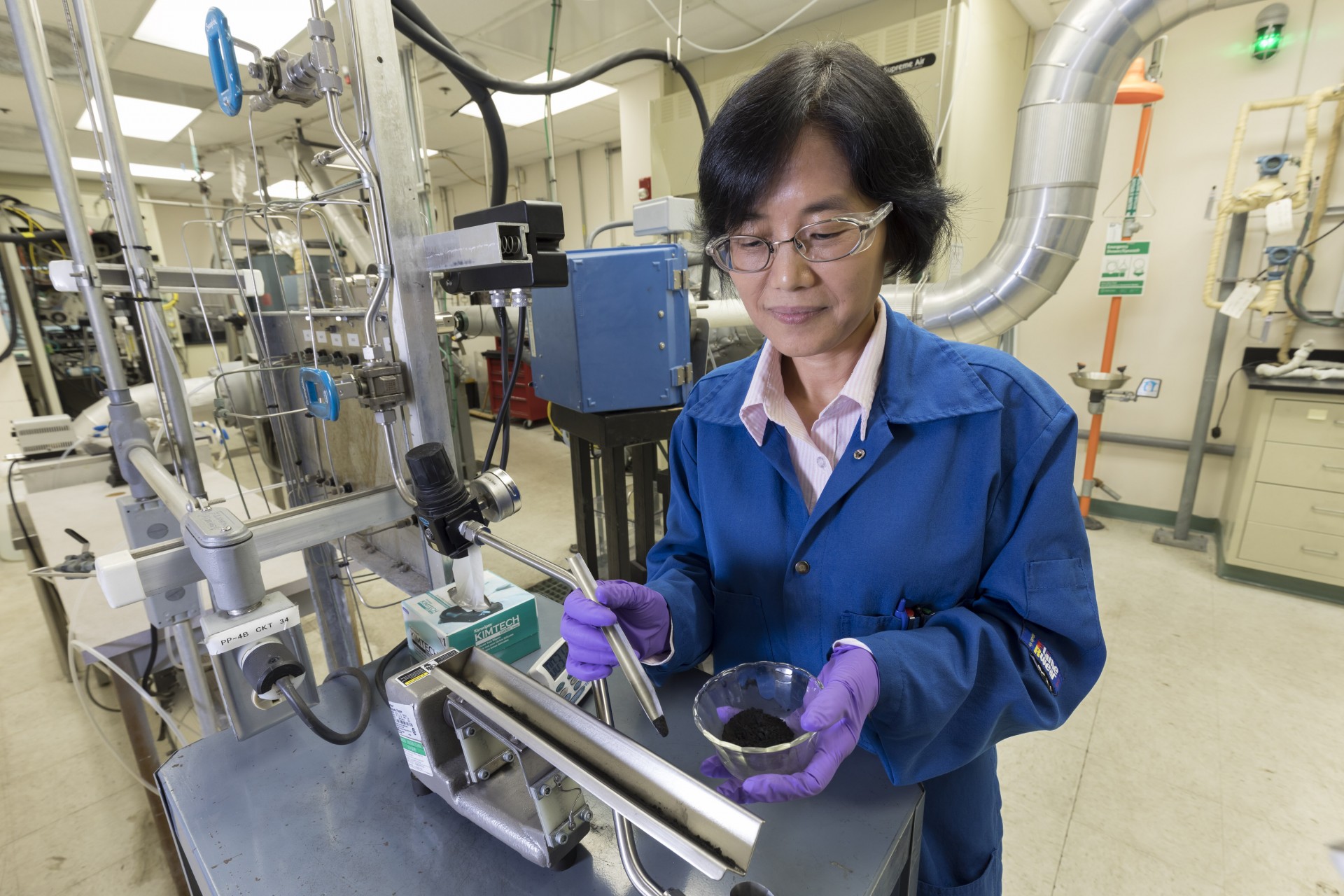

Albemarle’s Mercury Control Division is a full-service solutions provider to the coal-fired utility industry. Our team can connect you with the products, services and application-specific knowledge you need to ensure effective, efficient mercury control solutions. We offer:

- THE BROADEST PORTFOLIO of carbon-based (powdered activated carbon, or PAC) sorbents — including coal and coconut — backed by a world-leading position in bromine and bromine chemicals

- DEEP EXPERTISE in the established, effective technique of PAC injection into coal combustion gas streams — valuable knowledge that helps you identify PAC sorbents with the right properties for effective, lowest-cost mercury capture for your specific application

- INDUSTRY INNOVATIONS including proprietary PACs, mercury oxidizing chemicals (e.g., calcium bromide and sodium bromide), commercial-scale demonstration systems and a state-of-the-art pilot system to simulate flue gas mercury capture kinetics

- ADVANCED PAC SORBENTS for challenging conditions like acid gases and flue gas temperatures in excess of 300°F, as well as customer requirements including preserving fly ash sales and circulating sorbents through dry scrubber systems.

We know that recent standards have caused many utilities to cease operations due to the high costs of retrofitting or rebuilding their plants to ensure compliance. But where there are challenges, we see solutions. And as your industry partner, we’re actively committed to preserving coal as a trusted fuel source.

Albemarle pioneered the development of a method of mercury control in cement plants that utilizes the existing cement kiln particulate control device to capture the necessary amount of mercury. This method provides effective mercury mitigation without the additional added capital expense of a secondary baghouse. The method described is made possible through the use of Albemarle’s patented gas-phase brominated sorbents.

Albemarle’s C-PAC, a concrete-friendly, temperature insensitive sorbent, is injected into the existing particulate control system to capture the mercury. The sorbent must be temperature insensitive to operate at the elevated temperatures many times present in the existing cement kiln particulate control devices. The cement kiln dust (CKD) containing the mercury sorbent is shuttled to the product mill for inclusion in the final cement product. This is possible due to the concrete-friendly nature of the sorbent. Albemarle’s gas-phase brominated C-PAC mercury sorbent is both temperature insensitive and concrete-friendly and is perfect for this application.

Albemarle’s M-PACT is a cost-effective injection system capable of injection rates up to 1000 lbs/hr. The system requires minimal field installation and can be fed from super sacks, tanker or silo, depending upon customer’s preference and sorbent usage rate.

With our concrete-friendly sorbent, C-PAC, and compact injection system, M-PACT, Albemarle offers customers opportunities for effective mercury removal, high reliability and lower cost regulatory compliance.

Controlling steel industry mercury emissions can be done economically using both Albemarle’s M-PACT equipment, a small sorbent injection system, and proprietary gas-phase brominated B-PAC sorbent product, which is a cost-effective, reliable solution to meet your mercury control needs.

Albemarle’s M-PACT injection system has a programmable logic controller (PLC) based control system, which controls all of the injection system operations. Complete with temperature and flow instruments, M-PACT can monitor the flue gas in the injection location. The injection system's injection range was carefully selected in order to be able to provide reliable feed rates to variety of size boilers.

Albemarle’s gas-phase brominated B-PAC is a specially designed mercury sorbent consisting of a select powdered activated carbon (PAC) which has been brominated at elevated temperature to produce the sorbent. This sorbent has a very high mercury capacity, high thermal stability and rapid mercury reaction kinetics. B-PAC has been widely tested in numerous applications and found to provide mercury removals in excess of 90% in most cases.

Albemarle's Mercury Control Additives can be used to enhance the oxidation of the elemental mercury that is present in flue gas environments at power generation units and incinerators. Oxidized mercury is more readily removable via conventional pollution control processes and equipment.

Mercury Control Calcium Bromide Used to enhance the oxidation of the elemental mercury that is present in flue gas environments at power generation units and incinerators. Oxidized mercury is more readily removable via conventional pollution control processes and equipment.

Mercury Control Sodium Bromide, 45% Solution used to enhance the oxidation of the elemental mercury that is present in flue gas environments at power generation units and incinerators. Oxidized mercury is more readily removable via conventional pollution processes and equipment.

Mercury Control Sodium Bromide, 40% Solution used to enhance the oxidation of the elemental mercury that is present in flue gas environments at power generation units and incinerators. Oxidized mercury is more readily removable via conventional pollution processes and equipment.

Mercury Control Sodium Bromide Solid A white, crystalline, hygroscopic material.

Activated Carbon Injection is a proven technology to remove mercury in flue gas environments including utility, industrial boilers, electric arc furnace and cement plants.

Brominated PACs have been successful in removal rates of 90+ percent and are effective in reducing both elemental and oxidized mercury including plants burning PRB, Bituminous and mixtures of coals.

Today, Albemarle's patented gas-phase brominated PACs are being utilized by several plants and are effective in all particulate collection arrangements including fabric filters (baghouses) electrostatic precipitators (both hot-side and cold-side), and between particulate capture devices.

B-PAC is a gas-phase-brominated powdered activated carbon that can be used for the removal of both elemental and oxidized mercury from the flue gases of coal-fired boilers.

B-PAC+ is a proven method for oxidation of mercury and capture.

C-PAC is concrete-friendly brominated powdered activated carbon that can be used for the removal of both elemental and oxidized mercury in flue gases while not adversely affecting the ability of the resultant fly ash to be used as a substitute for cement in concretes.

H-PAC is a brominated powdered activated carbon that can be used for the removal of both elemental and oxidized mercury in flue gases with high temperatures up to 800°F.